What is Konjac gum E425?

Konjac gum E425 is also called konjac glucomannan or konjac flour. It is a natural odorless soluble fiber that is found in the konjac plant.

Konjac gum is used widely as a food additive in food: As thickeners and stabilizers: it can be used in jelly, jam, juice, vegetable juice, ice cream, ice cream and other cold drinks, solid drinks, seasoning powder and soup powder;

As a binder: it can be used in noodles, noodles, twisted skin, meatballs, ham, bread and cakes to enhance muscle strength and maintain a fresh state;

As a gelling agent: it can be used in a variety of soft candy, cowhide sugar and crystal sugar, can also be used to make bionic food;

Konjac plant

Amorophophallus Konjac, belonging to the Araceae perennial herb. Konjac plants mainly grow in mountainous areas and hilly areas with an altitude of 600-2500 meters. The ambient temperature requirement is about 16 degrees Celsius per year. It is mainly distributed in China and Japan in Asia. The Chinese konjac has a long history of planting, mainly in China. Western Hubei, Shaanxi, Yunnan, Guizhou, Sichuan and other provinces of the mountainous areas, including the mountains of western Hubei Province is the main producing area of high-quality konjac in China.

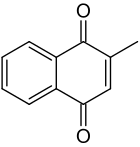

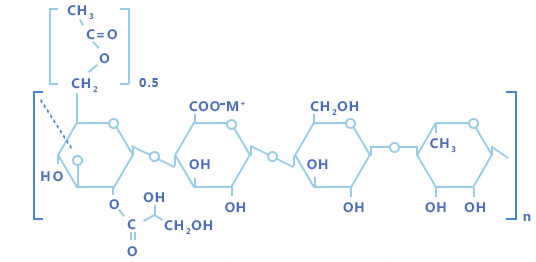

Konjac glucomannan

The main ingredient of konjac is the glucomannan contained in the bulb, which is a food with low thermal energy, low protein and high dietary fiber, and it also has various physical and chemical properties such as water-solubility, thickening, stability, suspension, gel, and film formation. Characteristics, so it is a natural health food and is an ideal food additive.

About 50% to 60% of glucomannan, 20-30% of starch, 2-5% of cellulose, 5-10% of crude fat, and 3-5% of soluble sugar (monosaccharide) And oligosaccharides) and 3-5% ash (mineral elements).

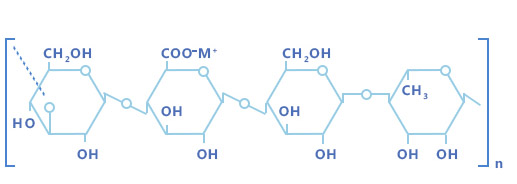

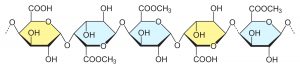

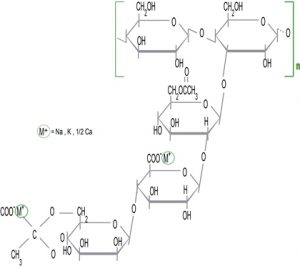

Studies have shown that konjac glucomannan is a polysaccharide with a molecular ratio of 1 million to 2 million that is a combination of D-glucose and D-mannose with a ratio of 1:1.6 and a β-(1-4) bond. Kelton, with the variety of konjac, processing methods and raw material storage time.

E425 Konjac gum Properties

Konjac gum is a gelling, thickening, suspending and film-forming agent.

Water solubility

Konjac glucomannan is soluble in cold and hot water and absorbs up to 100-200 times. The sol has a typical shear thinning phenomenon, ie, the apparent viscosity decreases with the increase of the shear rate, and is a typical pseudoplastic fluid. Therefore, the measurement conditions should be strictly controlled when the viscosity is measured.

Thickening

The konjac glucomannan has a large molecular weight, strong hydration ability and no charge characteristics that determine its excellent thickening properties. The 1% concentration of glucomannan solution has a viscosity of 5000-40000 mPa·s, which is the highest viscosity among natural thickeners. Konjac glucomannan has the ability to maintain a firm, wet tissue structure after heating the product. Others Thickeners do not show the same ability.

Stability

Compared with thickeners such as xanthan gum, guar gum, and locust bean gum, konjac glucomannan is not affected by salt in the system because it is non-ionic. At room temperature, the pH drops below 3.5 and remains stable. The use of konjac glucomannan in place of red locust bean gum for dairy products such as ice cream and dairy products can control ice crystal growth and stabilize its quality. Salt tolerance: Konjac solutions are tolerant to higher levels of salts.

Gelling

Konjac glucomannan has unique gel properties. Adding a small amount of alkali to a konjac sol at a concentration of 2% to 3%, heating in a water bath to 85° C. and allowing it to stand still for about two hours will result in a resilient, firm The irreversible gel, using its heat irreversible gel properties, can make a variety of foods, such as konjac cakes, noodles, bionic foods, vegetarian foods and so on.

As a gelling agent, konjac is quite unique for its ability to form thermo-reversible and thermo- irreversible gels under different conditions.

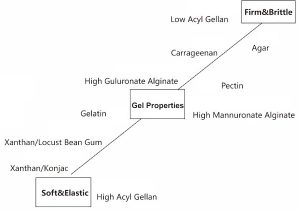

Thermo-irreversible gels

Konjac gum solution does not form gel because its acetyl group prevents the long chains of Glucomannan from approaching each other. However, it does form gel by heating to 85oC with mild alkali condition (pH 9-10) . This gel behaves stable to heat and it will remain stable under repeated heating at 100oC or even at 200oC. This property has been used to make a great variety of healthy/slim foods in Asian countries such as Konjac cakes, noodles, chips, imitating dishes for vegetarians (vegetarian shrimps, hams, steaks), bread, cookies, edible films, a fat replacer in hams, sausages, meat balls. Thermo-reversible gels: a combination of xanthan gum with konjac can form a gel at any pH although xanthan alone does not form a gel. At a pH of 5, the two gums show the greatest synergistic effect with a ratio of 2:3, konjac has a gelling ability very similar to carob gum but much more pronounced. Konjac is synergistic with Kappa-carrageenan to form strong water gels at very low dosages. It has been used for soft candy, water jelly, jam, ham, yogurt, puddings, ice cream, pet food to replace carob gum and gelatin. It has also been used in fruit/vegetable juice as suspending agent. It also as some interaction with starch.

Synergies with other colloids

Konjac glucomannan itself or it is compounded can have synergies with other colloids (such as Kappa-type carrageenan), it exhibits excellent synergies properties.

There is a clear synergistic effect between konjac glucomannan and Kappa carrageenan. After both are heated and cooled together, a brittle, elastically different gel can be formed. When both are 4:6 or 4.5:5.5, the gel strength reaches a maximum. Konjac glucomannan also has a good synergistic effect with xanthan gum, guar gum, locust bean gum, gellan gum and other colloids.

E425 Konjac gum Nutrition

Sugar

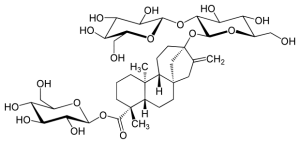

Glucomannan is the main component of konjac tuber, and its molecular formula is (C6H10O5)n, which is a heteropolysaccharide linked by d-glucose and d-mannan in a molar ratio of 1:1.6 to β-1,4 sugar linkages. Its content is about 44% to 64%, and the other is starch and other polysaccharides.

Proteins and Amino Acids

The crude protein content of konjac tubers ranges from 5% to 10%, and the total amount of 16 amino acids ranges from 6.8% to 8.0% (there are 7 essential amino acids). There are 18 kinds of amino acids in the konjac, and the total amount is 6.283%, of which the essential one is 2.634%, and the content of white konjac is 5.14% and 2.137%, respectively.

Minerals

Konjac contains a variety of minerals, tubers in the K, Ca, Mg, Fe, Mn, Cu, Co and other high content, according to Cui Xi and other reports, the human body needs a variety of trace elements and constant elements in the konjac content is considerable.

Other nutrition

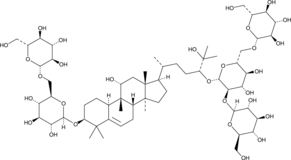

Alkaloid content of 1% to 2%, toxic, but also contains more calcium oxalate crystals, so the konjac must be processed before eating. In addition, konjac can be processed to separate a variety of substances such as betulinic acid, beta-sitosterol, metoprol, xylose, and carotene, thiamine, riboflavin, ascorbic acid, and the like.

E425 Konjac gum Benefits

Weight loss

The main ingredient of konjac is Konjac glucomannan, an edible vegetable fiber that is not easily digested. Konjac glucomannan is extremely low in calories, and has the characteristics of strong water absorption, high viscosity, and high expansion rate. It can expand 20 to 100 times after absorbing gastric juice in the stomach, giving rise to satiety, and it will not increase people’s dietary pleasure at the same time. Fat, without deliberate dieting, can achieve a balanced diet, so as to achieve the desired effect of weight loss.

Antihypertensive anticancer

Konjac can absorb intestinal and stomach cholesterol and promote its excretion during gastrointestinal retention. Konjac glucomannan has a certain influence on bile secretion, which can prevent the absorption of cholesterol by human body to a certain extent, and can effectively interfere with the metabolic function of cancer cells. After entering the human intestine, konjac gel forms semipermeable membranes with different pore sizes and adheres to the intestinal wall, which can block the invasion of harmful substances including carcinogens, thereby detoxifying and preventing thyroid cancer, gastric cardia cancer, etc. Colon cancer, nasopharyngeal cancer and other cancers.

Calcium supplement

Experiments have shown that calcium in konjac foods elutes more easily, especially in acidic solutions. When people eat Konjac glucomannan, the horny konjac comes into contact with the acidic gastric juice, and the calcium begins to melt and then absorbs from the stomach and stomach, so as to achieve the effect of calcium supplementation.

Cleaning stomach

After eating Konjac glucomannan, the digestion and absorption are slow. A large number of soluble plant fibers promote gastrointestinal motility, which can reduce the residence time of harmful substances in the stomach, intestine and gallbladder, effectively protect the gastric mucosa and clean the stomach wall.

Detoxification

Its rich plant cellulose helps to activate the intestinal function, accelerate the excretion of harmful toxins in the body, prevent and reduce the occurrence of diseases of the intestinal system diseases.

E425 Konjac gum use and application in food

Konjac gum has various use properties such as hydrophilicity, thickening property, stability, emulsifying property, suspending property, gelling property and film forming property, and can be used for making various food additives, and is widely used in the food industry.

Konjac gum can be used as Stabilizer for ice cream, smooth and delicate taste; when used in bakery food such as cakes, it can make the appearance of the product smooth, loose texture; it can increase the strength of the line surface, increase noodle toughness. Konjac gum can be as a foam stabilizer, inverted cup after the bubble is small and uniform, long hanging cup; as a clarifier of juice and wine; as a food preservative, can inhibit the reproduction of aerobic microorganisms, extend the preservation period of eggs, meat, fish, fruits and vegetables. Using the film-forming properties of Konjac gum, microcapsules can be produced. The products produced by the microcapsule technology can protect the embedded micro-particle materials avoid adverse reactions with other components, and at the same time isolate them from external environmental factors, while maintaining the original color, fragrance and taste of the materials. Reducing the deterioration or prolonging the shelf life, improving the product quality, making some materials that are not easy to store or process become stable, and make the solids with good fluidity extend the use range, simplifying the production process.

E425 Konjac gum In Health capsule

In the health care products, Konjac glucomannan solution used as binder in the manufacture of tablets and capsule. In the manufacture of tablets & capsule needed a filler material that may break the tablet in the stomach. Konjac gum usually used in starch or gelatin which has properties spread across the water.

E425 Konjac gum In Meal products

Konjac glucomannan is a fiber can be soluble in cold and hot water, its water absorbability can reach 100-200 times, it can produce satiety through its water retention, and at the same time it is a kind of dietary fiber and does not contain calories. Konjac Glucomannan swells in the stomach and absorbs fat, and assists lipolysis during gastrointestinal motility. Therefore, konjac glucomannan can be used to make diet foods, So it is widely used in weight loss products.

E425 Konjac gum In Meat products

Konjac gum plays a role of gelling, water retention, emulsification, and enhancement of elasticity in meat products, which can effectively increase the water holding capacity of the meat, also improve the texture of the product, and improve the elasticity and slicing functions of the meat products.

Adding a proper amount of konjac flour in sausages, ham sausages, luncheon meatballs, meatballs, fish balls and other meat products can play a role in bonding, refreshing, and increasing volume; adding konjac flour in meat emulsions can increase the water absorption of meat emulsions and improve Structure makes it flexible. Using konjac flour to replace some of the fat in meat products can improve the structural characteristics of the aqueous phase and produce a creamy, smooth, sticky consistency. In particular, the use of konjac flour and carrageenan compound in low-fat meat emulsions can significantly improve the quality of products. Structure, improve the special water, thus giving low-fat meat clam products juicy, smooth taste, to meet the requirements of high-fat meat products.

E425 Konjac gum In Vegetarian products

As it is a soluble fiber, Konjac gum can be used in vegetarian products for people who are strict in Vegetarian products.

Konjac flour is prepared under alkaline heating conditions to form a thermally irreversible gel. There are more and more varieties of konjac foods, mainly konjac fans, konjac rice, konjac noodles, konjac kidney flowers, konjac maw, konjac knot, konjac shrimp, konjac tofu, prime abalone, and prime sea cucumber.

E425 Konjac gum In Bean Curd products

During traditional preparation of bean curd,0.1% konjac Glucomannan which is the weight of the material is processed with warm water to obtain paste, add the paste into the bean liquor before its cooking, stir well and heat to boil, add the gypsum into the boiled liquor, the bean curd made of konjac and bean is so produced.

E425 Konjac gum In Noodle products

Adding konjac flour to noodles enhances the toughness of the noodles, makes the noodles boiled more stable, easier to cook. At the same time, the products can withstand high-intensity cooking, and the taste of the noodles is even smoother and softer.

The storage period can be lengthened and the toughness can be enhanced, the noodles become more stable for cooking without muddy soup, the breakable noodles are obviously reduced, and the noodles taste smoothly and soft, and the degree of finish of the surface is improved evidently.

Add a certain amount of konjac Glucomannan to fine vermicelli , the products weakness such as breakable property and muddling property can be corrected, and the products can stand hard cooking and chewing with good mouth feeling, and the color of the product will always maintain unchanged. The adding ratio (on dried basis) of konjac Glucomannan for various powder materials are as following: 0.1%~0.5% for rice noodles and bean powder, 0.5%~1.0% for corn powder, potato powder and sweet potato powder.

E425 Konjac gum In Beverage

Konjac flour has thickening, suspending, emulsifying and stability properties that can improve the quality of beverages.

Adding konjac flour to protein drinks will make the quality of the drinks more stable, less prone to sedimentation, and have a more thick mouthfeel.

The use of konjac flour to yoghurt and a variety of artificially acidified beverages will cause the sedimentation and delamination of the beverage to disappear and prolong the settling time.

Adding a small amount of konjac flour in a drink with flesh will give the flesh a better suspension effect and taste and appearance will be better.

When a small amount of konjac flour is added to the ice cream, the amount of added fat can be reduced, the viscosity of the solution will be increased, the water absorption will be enhanced, and the expansion rate of the product will also be increased, which can effectively prevent the formation of crystals of smooth sand and achieve a higher level of quality. Silky texture.

Because konjac Glucomannan has thickening property, suspension property, emulsifying property, and stabilization property, and the beverage quality can be modified with the use of konjac glucomannan. Add a quantity of konjac Glucomannan which is 0.5%~1.0% the weight of the materials into the protein beverage, oil extracting and precipitate accumulating can not develop and the beverage quality is more stable with heavy taste.

To fermented acidophilus milk, fruit acidophilus milk or various dairy beverage with artificial acidifying agent, add a quantity of konjac Glucomannan which is 0.30%~0.35% the weight of the materials, the precipitate accumulation and demixion can not be observed in case the products contained in bottle is preserved for 3 months and the products contained in readily pull-off aluminum tin is preserved for 12 months.

To fruitage beverage, add a small amount of konjac glucomanann and complex gel, the suspension effect can be bettered and mouth feeling and appearance can be adjusted.

E425 Konjac gum In Bread

During bread preparation, add a quantity of konjac Glucomannan which is 0.1% the weight of the flour, the ratio of amount of the air hole and swelling level are both increased, the volume of bread is enlarged with exquisite and homogeneous fabric,the bread becomes more elastic and delicious with soft and crisp mouth feeling. Excessive amount is not recommended, in case of over-adding, the thorough swelling of protein granule in water will be impeded. With the use of konjac Glucomannan in flour, the volume of the steamed bread can be enlarged with soft and delicious flavour.

E425 Konjac gum In Cake

Add a certain amount of konjac Glucomannan to the cake base, the product will become expanded and soft with good moisture-keeping ability, no crumb and no tooth-sticking is observed during eating, and the cake taste soft and exquisite and its shelf life can be doubled.

E425 Konjac gum In Jelly

Using Carrageenan blend with konjac Glucomannan as gelling agent can make good-quality, low-price jelly, so it is a better choice comparing to other gels such as agar, gelatin and pectin, etc. The jelly produced with our company’s jelly powder has virtues of elastic feeling, better taste and good transparency. The use level is 0.2-0.5% of jelly quantity.

E425 Konjac gum In Jam & Sauce

Konjac glucomannan has also been widely used in flavoring sauce& jam, such as carrot Sauce and

Tomato Sauce with its high viscosity and shearing property and diluting property. Under an external force, shearing and diluting occur in glucomannan, make the jam and sauce products with konjac glucomannan easy to flow and apply. When the external power stops, the fluidity of the applied jam and sauce is reduced and the adhesion ability is enhanced.

E425 Konjac gum In Pet Food

The Konjac gum acts with water holding, elasticity enhancing and strong adsorbability in pet food.

Konjac gum helps to absorb the poisonous?metal and other toxins to decrease the damage of the toxins to the liver.

Konjac gum also helps to absorb and clear away the pathogen in the intestinal?tract to enhance the immunity of the pet.

E425 Konjac gum Side effects

Glucomannan, like other types of soluble fiber, can cause gastrointestinal side effects when you suddenly increase the amount you consume. These can include bloating, stomach pains, loose stools, flatulence and diarrhea.

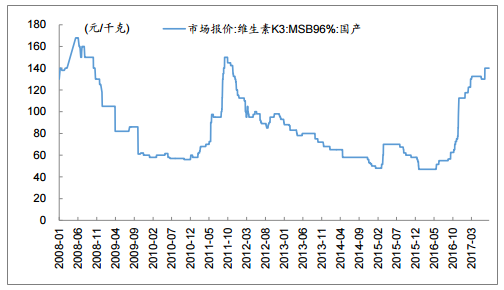

E425 Konjac gum Markets

Konjac is a plant of the genus Amorphophallus, Araceae and a perennial tuber herbal plant. Konjac gum is a high-molecular weight polysaccharides extracted from the tubers of various types of konjacs and its main ingredient is glucomannan (KGM). Konjac gum contains high water-soluble edible fibers, minerals, trace elements and 16 types of amino acids. It is low-energy, low-protein and low-fat.

Konjac gum has characteristic of hydrophilic, thickening, stabilizing, suspending, gelling and film forming, Konjac gum is widely applied in the food industry, for example, meat products, dairy products, candies, jellies and etc. It is used to improve the texture, mouth feel and gelling effects of food products. Konjac gum is also extensively applied in pharmacy, health care, bioengineering, petroleum, textile, tobacco processing and cosmetic industries.

In recent years, the food market trend is moving towards high fiber. Many researches show that glucomannan, as an edible fiber from konjac prevents rising of blood sugar index, is good for the prevention of diabetes. Moreover, it can also inhibit cholesterol absorption, enhance bile acid metabolism and improve digestion. It is recognized in preventing high blood pressure, high blood fat, obesity and diseases of the digestive system. With more study and better understanding of the health benefits that fiber food offered, konjac, as a functional ingredient of foods, is expected to be more common in food industry in the future.

E425 Konjac Gum types in the market

Common konjac fine flour

Common konjac fine flour is defined as the kind of konjac flour which is basically free from starch and other impurities when konjac tuber slices or chips have been dry-processed with physical procedures or when fresh konjac tuber has been wet-processed with edible alcohol and more than 90% of whose particles have a size in the range of 0.125 mm~0.335 mm.

Common konjac particulate flour

Common konjac particulate flour is defined as the kind of konjac flour which is basically free from starch and other impurities when konjac tuber slices or chips have been dry-processed with physical procedures or when fresh konjac tuber has been wet-processed with edible alcohol and more than 90% of whose particles have a size of ≤0.125 mm.

Purified konjac fine flour

White color. Granularity more than 120 meshes. Smellless. Quick in dissolving. Of high viscosity and high transparency. Processing procedures: Use konjac fine flour as the raw material, which is purified and removed of starch, ashes, fiber, pigment, alkaloid and other impurities, so as to obtain highly purified glucomannan, with a content of 80-95% on air-dried basis.

Purified konjac fine flour is defined as the kind of konjac flour which has a glucomannan content of more than 85% when fresh konjac tuber has been wet-processed with edible alcohol or when konjac fine flour has been purified with edible alcohol and more than 90% of whose particles have a size in the range of 0.125 mm~0.335 mm.

Purified konjac particulate flour

Purified konjac particulate flour is defined as the kind of konjac flour which has a glucomannan content of more than 85% when fresh konjac tuber has been wet-processed with edible alcohol or when konjac fine flour has been purified with edible alcohol and more than 90% of whose particles have a size of ≤ 0.125 mm.

Konjac Gum Specifications

| Item/Type |

Konjac Powder |

Konjac Powder |

Konjac Gum |

| Particle Size(Mesh) |

90% pass 40-100 mesh |

90% pass 120 mesh |

90% pass 120 mesh |

| Appearance & Oder |

Yellowish to white powder.

Yellowish with a few brown particles.

Distinctive smell of kojac. |

Yellowish to white powder.

Yellowish with a few brown particles.

brown particles Slight smell of konjac. |

white to Yellowish with a few brown particies,odorlessness |

| Glucomannan Content(%) |

≥ 60 |

≥ 70 |

≥ 60 |

≥ 65 |

≥ 70 |

≥ 80 |

≥ 80 |

≥ 85 |

≥ 80 |

| Viscosity(mPa▪s) |

≥ 6000 |

≥ 15000 |

≥ 5000 |

≥ 10000 |

≥ 15000 |

≥ 20000 |

≥ 25000 |

≥ 36000 |

≥ 18000 |

Transparency(%)

(0.5% solution 550nm) |

— |

≥ 65 |

— |

≥ 65 |

≥ 65 |

≥ 70 |

≥ 70 |

≥ 75 |

≥ 80 |

| Moisture(%) |

≤ 12 |

≤ 11 |

≤ 10 |

| Total Ash(%) |

≤ 4.5 |

≤ 3.0 |

| Lead(Pb)(mg/kg) |

≤ 0.8 |

| Arsenic(As)(mg/kg) |

≤ 3.0 |

| Sulfur Dioxide(SO2)(g/kg) |

≤ 2.0 |

≤ 0.9 |

| pH(1% Aqueous Solution) |

5.0-7.0 |

| Total Plate Count(cfu/g) |

≤ 10000 |

≤ 2000 |

| Yeast & Moulds(cfu/g) |

≤ 500 |

≤ 100 |

| Remark 1 |

Viscosity test method:1% solution,30℃ dissolved,NDJ-1 type viscometer,4# spindle,12r/min. |

| Remark 2 |

Special specifications products(low sulfur,high transparency.etc.)can be produced according to customer demand. |

Konjac gum E425 manufacturers

China is the big Konjac gum manufacturers and export country in the world.

There are several Konjac gum manufacturers in China and abroad, as you know, the price of China suppliers can be better than abroad manufacturers. We have worked with China top manufacturer for years, we would like to recommend our selected Konjac gum suppliers to you if you would like to save your purchasing cost with the same quality compared with abroad manufacturers. Konjac gum Samples are available if you need it for further test after accept the price.

Konjac gum E425 price

As you know, there are many types of Common konjac fine flour, purified konjac fine flour, transparent konjac fine flour in the market. The price is based on different types. Please contact us if you need a price idea.

Where to buy Konjac gum E425?

All the products listed in our website are from the manufacturers we have worked together for many years. The professional working experience backup our confidence to their quality. We can supply Konjac gum E425 for many Specifications and we can be your suppliers in China.

By using the appropriate Konjac gum E425 types in your food, the formulator can create suitable products with good gelling agent, thickener and stabilizer.

We’re committed to the quality and safety of our ingredients. We know that our customers expect us to use only the highest quality and healthiest ingredients available, and we do everything we can to satisfy those expectations. We feel confident in our choice to choose top Konjac gum E425 manufacturer brand.

If you have any other questions, please email us through: info@foodsweeteners.com