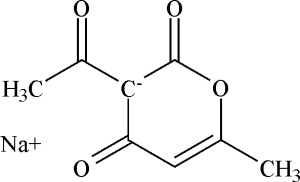

Sodium Alginate E401 can be used in Food, Beverage, Pharmaceutical, Health & Personal care products, Agriculture/Animal Feed/Poultry. Sodium Alginate E401 is used as a thickening and emulsifying agent in salads, puddings, jams, tomato juices, canned products, ice creams, yogurts, creams, and cheeses.

Sodium Alginate E401 use as follows:

Sodium Alginate E401 Application and uses:

In Food Industry

(1). Stabilizer

As a stabilizer of ice cream replacing starch and carrageenan, Sodium Alginate E401 can avoid of ice crystal and make the product tasty. It also applies to the mixed drinks, such as ice lolly, iced fruit juice and iced milk, etc. When adding some into dairy products like refined cheese, canned cream and dry cheese, the final product will not stick to the package. Moreover, Sodium Alginate can keep the product fine and avoid of splitting open if it is used as a cover of mild food.

(2). Thickener and Emulsion

Sodium Alginate E401 can raise the product’s stabilization and decrease the liquid out when it is used in salad flavoring, pudding jam, tomato ketchup and the canned products.

(3). Hydration

Sodium Alginate will make noodle, vermicelli or ice powder have a strong cohesiveness, pulling, bending and reduce breaking, special suitable in the less gluten content of wheat flour. Sodium Alginate E401 also can equal the products’ internal form and hold water so that it can be kept for a long time. Adding some into iced sweet products, Sodium Alginate E401 will come into being a protecting cover against heated quickly, and it can quicken the flavor sending forth, raise melting point of the products.

(4). Coacervation

Sodium Alginate E401 suits to make kinds of gel product, which can be kept the fine state, non-leakage and contraction. So it also fits iced products and man-made products. Using this specific property, it can be used as a cover for fruit, meat and seaweed products away from air and keep it stored longer. In addition, it also can be used as the sugar coating of bread, the cover of filling and cake and the auto-coagulant of canned food, which will not change in high/low temperature and acid conditions. It also can replace carrageenan to make a crystal soft sugar, elastic, unstick, transparent.

Specifications of Sodium Alginate

|

Industry Grade

|

Food Grade

|

||

|

Agriculture Department Standard SC137-85

|

Export Standard

|

Food additive standard

|

|

| Mesh size | As required | As required | |

| Viscosity mPa.s | 80-800 | As required | ≥150 |

| Moisture % | ≤15.0 | ≤15.0 | ≤15.0 |

| PH | 6.0-7.5 | 6.5-7.5 | 6.0-8.0 |

| Ca content% | ≤0.3 | ≤0.3;≤0.2 | |

| Ash | ≤24 | 30-37 sulfate ash | |

| Viscosity decline % | ≤20 | No below the requirement in the contract after one year | |

| White degree % | ≥30 | ||

| Insoluble matter in water % | ≤0.6 | ≤0.3 | |

| transparency cm | ≥4 | ||

| Heavy metal % | ≤0.004 | ||

| Arsenate % | ≤0.0002 | ||

| Lead (Pb) % | ≤0.0004 | ||